Executive Summary

This report refers to the performance trial of the COOLNOMIX energy-saving technology at Singtel flagship data centre location at 7 Bedok South Road, Singapore.

In close communication with Singtel management & engineering staff and after careful review of suitable trial sites, two COOLNOMIX AR-0C energy-saving devices were deployed in the East Wing, LV Switch Room One.

Following two weeks of base-line measurements with COOLNOMIX in by-pass mode and twice over two week periods of COOLNOMIX in control (i.e. COOLNOMIX switched ON), the average daily energy consumption taken for each period demonstrates an energy-savings of 28.6%.

The result more than adequately satisfies the original trial objective and the next step will be to prepare & sign-off on the production rollout proposal with the ultimate goal of assisting Singtel to reduce their CO2 emission and start generating valuable energy-savings.

| Trial Period | COOLNOMIX in by-pass mode | COOLNOMIX switched ON | % Energy-Savings |

| May 1st – June 28th | 21.36 kWh | 15.25 kWh | 28.6% |

i. Introduction

Anvita Engineering provides energy-optimization and clean technology solutions to customers in the AsiaPacific region. Anvita Engineering is the Authorized Distributor for the COOLNOMIX line of products in Singapore, Malaysia and India.

The Technology

COOLNOMIX® ORS®, is a patented algorithmic energy-optimization control methodology, which stands for Optimized Refrigerant Supply. Incorporating two temperature sensors, it monitors the thermodynamic (room temperature) and the hydraulic (refrigerant supply) performance of the cooling system to eliminate periods of unnecessary work.

The Client

The Singtel Group (“Singtel”) is Asia’s leading communications group providing a diverse range of services including fixed, mobile, data, internet, TV, infocomms technology (ICT) and digital solutions. Headquartered in Singapore, Singtel has more than 130 years of operating experience and played a pivotal role in the country’s development as a major communications hub. Following conversations with both senior and middle management, it became evident that Singtel is 100% committed to conduct their local as well as regional expansion in an environmental friendly and sustainable manner. Reducing carbon emissions, as well as, promoting and integrating energy-savings solutions wherever feasible.

Trial Objectives

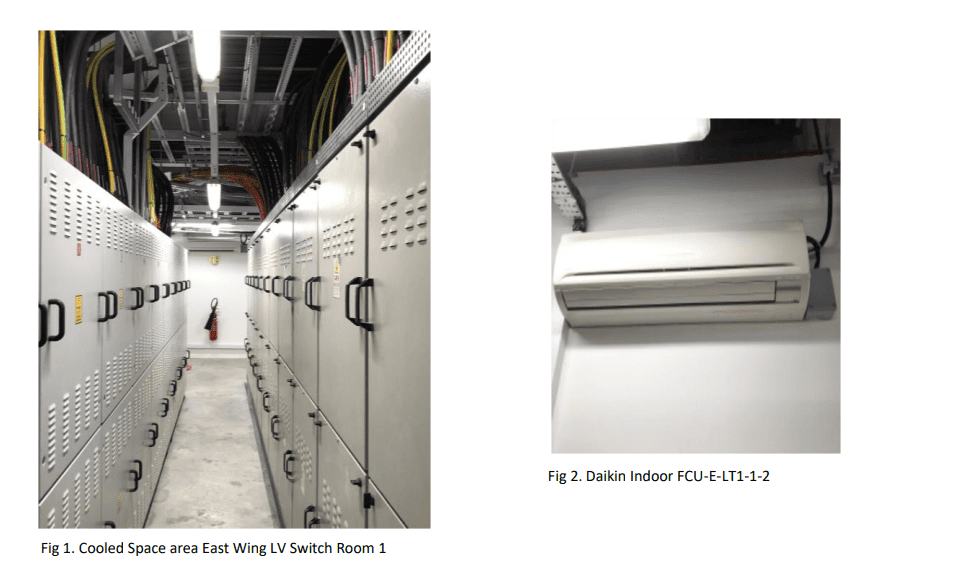

The purpose of the trial would be to demonstrate an indicative energy-savings of 25% for existing airconditioning systems installed at the Client premises located at 7 Bedok South Road, Singapore. The airconditioning system identified as the best candidate for this trial (reference is made to Trial Run proposal dated February 22nd) being the East Wing, LV Switch Room 1. It is to be noted that the energy-savings may vary between systems and across the seasons, and that achievement of ongoing energy-savings is dependent on professional and regular maintenance & servicing of the installed cooling systems.

ii. Trial Setup

The LV Switch Room 1 is located in the East Wing of the premises on 7 Bedok South Road, Singapore. The cooling systems installed are two inverter-based Daikin VRV air-conditioners.

The trial was set up as follows:

COOLNOMIX

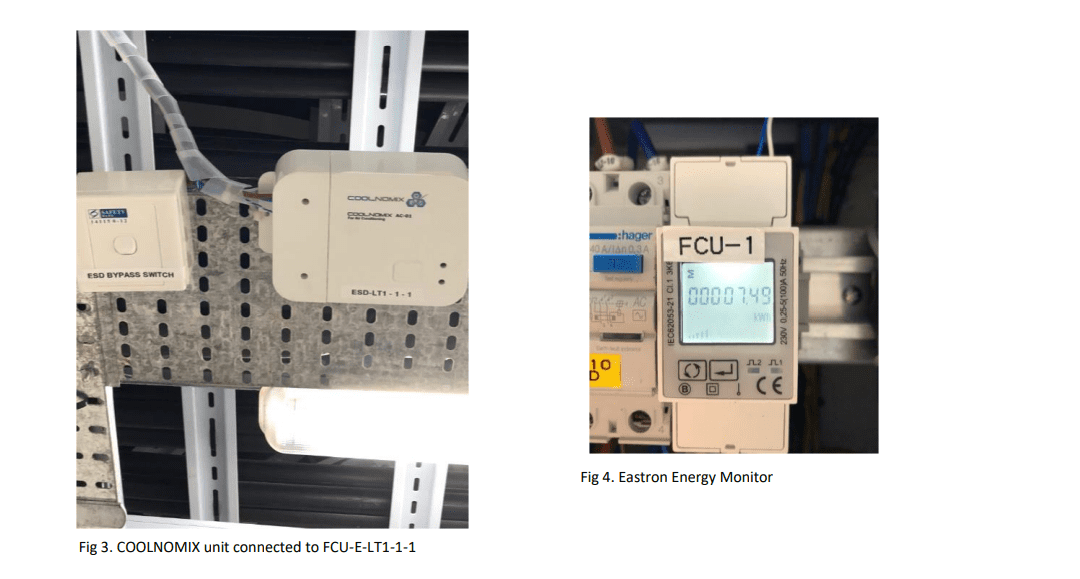

- A total of two COOLNOMIX energy-saving retrofit units were installed as closely as possible to respective Fan Coil Unit (FCU) and connected via the FCU’s existing thermistor using the COOLNOMIX series connection method.

- Given that the installed cooling systems work in two by two pairs and change-over sequence, it was discussed & found to be acceptable that for the duration of the trial the two COOLNOMIX units were connected to the FCU-E-LT1-1-1 and FCU-E-LT1-1-2 which consequently will run for 100% throughout the duration of the two-week trial.

- The temperature setting of the COOLNOMIX unit followed the set temperature of the existing thermostat.

ENERGY MONITOR

- One single-phase Eastron Energy Monitor was installed within the DB to monitor the power consumption of the condensing unit. This was achieved by connecting one CT clamp of the monitor to the corresponding power supply of the condensing unit.

- The Energy Monitor was connected via a secure modem/gateway to a cloud-based monitoring platform allowing remote login viewing both live and historic data.

TEMPERATURE LOGGER

- One Tenmars temperature logger was installed within the cooled room to record the maximum and minimum temperature throughout the trial period. In addition to the temperature logger, the Client already has a High Temp alarm integrated into the system.

Trial Duration

The trial was conducted over three identical time periods in order to obtain an accurate picture of the average daily energy consumption and reduce the impact of any abnormal high or low peak load conditions. The time periods selected were comparable in ambient temperature profile and solar heat gain given Singapore’s equatorial belt location at around 1º north of the equator.

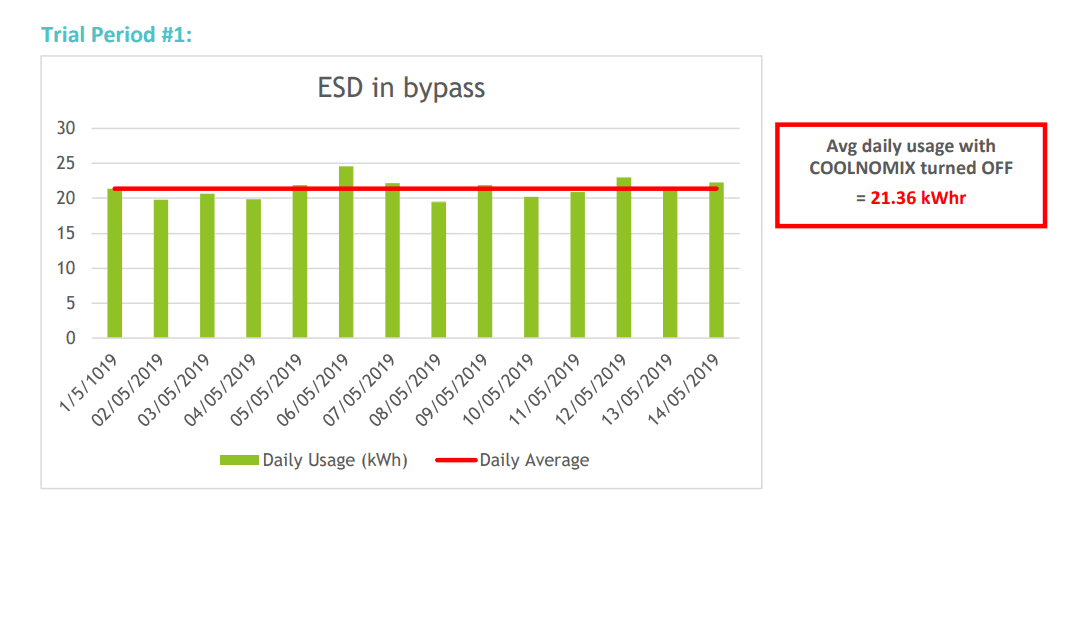

- Period #1 (May 1 – 14): COOLNOMIX units in by-pass mode

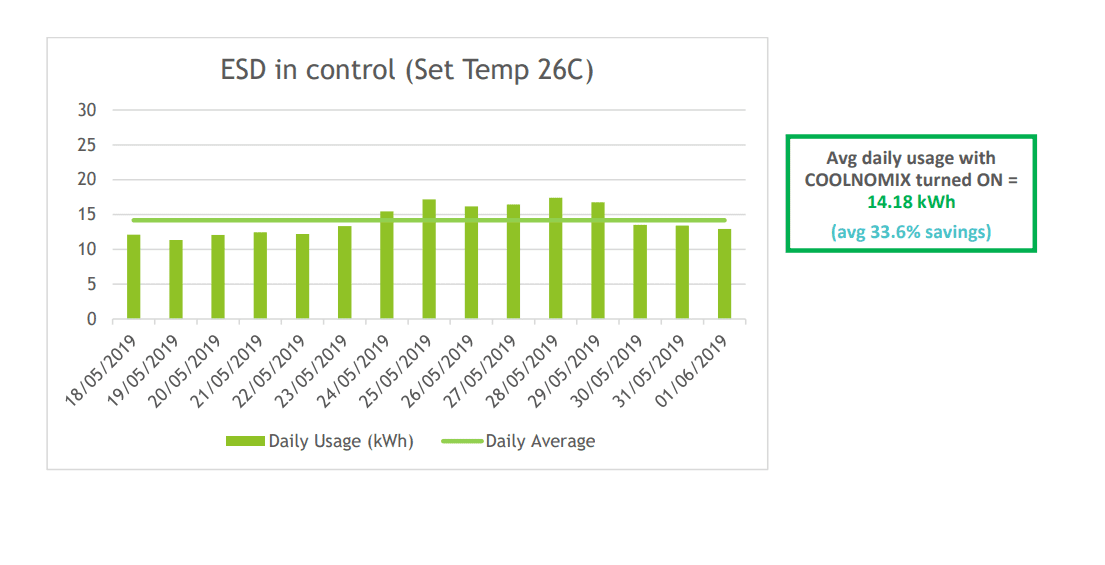

- Period #2 (May 18 – June 3): COOLNOMIX units switched ON (Set Temp 26 degC)

- Period #3 (June 5 – June 28): COOLNOMIX units switched ON (Set Temp 25 degC)

iii. Trial Results

Analysis of trial results

After careful analysis of the detailed readings throughout the trial period, we established an average daily consumption of 21.36 kWh with COOLNOMIX in by-pass mode and 15.25 kWh with COOLNOMIX switched ON. Hence demonstrating an energy-savings of 28.6%. See below graphs.

In fact, if the Client were to consider setting the COOLNOMIX unit at one degree higher (i.e. 26 degrees Celsius) the average daily usage would drop down to an average 14.18 kWh saving on another 1kWh per day. See graph under Trial Period #3.

Note that in agreement with the Client’s engineering team, the trial was extended with two weeks due to a cool weather & heavy rain fall on June 7-9 (see Trial Period #2).

Trial Period #2:

Trial Period #3: